|

||||

|

||||

|

||||

Net Dynamic Menu by Vista-Buttons.com v4.3.0

We are listed on and

|

How to drive a mast down the roadAndHow to lower a mast without a craneBy: Scott Fratcher - Marine Engineer/Captain. Adapted from "Businesses run from a cruising boat or How to make money with boat"

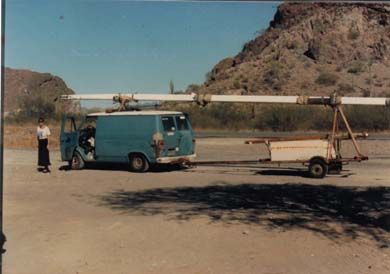

Driving a mast down the roadThis rig made it 1500 miles!Raising and lowering masts means you might have to move a mast by road. Moving a mast is pretty easy if you know the trick. The photo above is a mast that we drove from San Francisco all the way to La Paz, Mexico down the 700-mile twisty tourney Baja highway.

The trick here is to get the mast up and over the vehicle. If we just try to tow the mast the car and trailer will be too long to legally drive down the road.

We have to build a carriage for the mast on top of the tow vehicle and another for the far end of the mast on the trailer. The tow vehicle mast carriage will have to support the weight of the mast and be strong enough to pull the mast along. A couple lines run aft take the pull of the mast and two lines forward stop the mast from sliding forward during a crash stop.

The trailer simply holds the mast up and allows the mast to slide inside a greased track. The sliding track we used here was just some greased teak strips lashed to the mast. The track is needed because the mast carriage on the tow vehicle pivots at a different location than the trailer to the vehicle. When you turn this causes the distance between the mast carriage on the tow vehicle and the carriage on the trailer to change length.

Lowering a mast without a crane

Yachts have to lower their masts for all types of reasons. Maybe they found the mast step to be corroded, or the masthead had a failure that can only be dealt with from land, or maybe it's just time for maintenance. In this article were going to talk about lowering a mast when no crane is available. For example, perhaps your vessel is in a remote location or perhaps the cost of a crane is out of the DIY budget. . The steps to unstopping a mast without a crane are:

Estimate the mast weightStart by estimating the weight of the mast you plan to lift. You might have to do some investigating but don't forget to add the weight of the mast winches, rigging, and electrical cables.

Rig up some sailing blocks capable of lifting the rig weight six times over. This is our six to one safety margin. Don't skimp on the safety margin. If a little sailing block stamped 1000 kg looks too small then it probably is. Even if you plan to lift a small rig at least 12mm line and blocks should be used simply so your hands can effectively grab the line.

Finding something strong to lift fromWhen raising a mast without a crane the two most commonly used lifting points are: * Other boats, or

A bridge (or other over the water structure) can be the most stable, but often takes time to gain permission. If we can find a good solid land based support to lift from then we only have to consider the tide.

Lifting from other boats tend to be easier to arrange, but more complicated to rig. Lifting from another boat can be done in two ways. Either by side tying one boat to each side to make an even lift or using a gaff boom.

Note-Spinker poles can be used in place of a gaff boom, but pay careful attention to the load where the spinker pole attaches to the lifting mast. The force during lift can be extreme and spiniker poles may induce a "rolling" motion at the point of mast attachment stressing the fittings. Gaff booms push straight into the mast center and thus don't suffer this problem.

Lets look at lifting from other boats rafted alongside. The surrounding boats will not actually lift the mast, but will just provide a support point. The actual lift will be done through a block simply supported by the surrounding rigs.

We want a lifting point directly above our mast. To get this we take a line from the masthead of each boat and tie them together into a bowline. In practice we want two lines from each boat. One line as a safety and one to hold the load, so we have four lines forming four bowlines that are secured together looking like one thick loop.

Attach the block and tackle to the bowlines and raise them with the block till they are over the mast. We should now have a block and tackle ready to lift and the bitter end on deck.

Attaching to the mastTo lift a mast we must find away of attaching a line to it. We need a connection that is soft, easy to build, and available on the yacht. I like to make collar from a short bit of good high quality sailing line. Were going to make two lifting collars so, take two lines and wrap them around the mast about four times each. Make the bitter ends fast to themselves using bowlines. The two collars (one to lift and one for a safety) can now be slid up and down the mast. Next we make the make way to hold the collars in the chosen position.

We make an adjustable collar by connecting lines from the collars to cleats at the base of the mast. This allows us to easily adjust the height of the collar from deck and provides double security. Remember, for every section of this lift we want two support lines. One to lift and one for security.

Note-Often I see people use the spreaders as a "stop" for the rope collar when lifting a mast. This is not a good idea for two reason. First you're not in control of where the lifting collar lands. It may grab a spreader or electrical line in an unpredictable way causing more work. Second the spreader base is not meant to carry the upward load of lifting a mast. You can never predict exactly how a rig is going to lift so minimizing any "unknowns" is important.

Find about the center point of the mast and plan on lifting from this point. You don't want to be lifting from below the half way point as the mast may flip upside down uncontrollably once all stays have been removed. Wooden tapered masts are less of a balance risk, but aluminum extrusions must be looked at carefully as they often have no taper thus you must lift from above the middle/balance point.

Lifting rigWe can now turn our attention to the lifting rig. For a deck stepped mast I like to use a four to one purchase tailed to a winch at the base of the mast. The winch on the base of the mast should be well mounted as it will be lifting one quarter the weight of the mast.

The top of the four to one block and tackle is attached to your chosen lift point weather this is the end of your gaff boom, spinnaker pole or whatever point you are using to lift from.

As a test start cranking on the winch to take some load on the lifting system. The stays should not be loose yet so this is a good safe test. Take a hefty amount of strain on your lifting rig and inspect the complete system.

Look at the winch bases for signs of failure. Examine the cleats that are taking load. Inspect each section of the block and tackle with binoculars. Check for twists or blocks side loading.

Consider the path to deck once you begin lowering the mast. Verify it will not twist causing the block to jam. This is your last chance to find and correct any suspect areas of your planned lift.

Lift and lower to deckIf the lifting rig has passed all inspections it's time to lift and lower the mast to deck. Every person on deck should know what they are expected to do. All spectators should be clear. This is a perfect time for some people to be in the dingy taking photos. We can now disconnect the uppers, head stays and backstays relying solely on the lowers.

Slacken the lowers till they are floppy loose and take tension on the block and tackle.

We should see the mast begin to lift and the lowers go tight. If not then the mast is stuck in the base or something else is preventing the mast from lifting.

It's common for the mast base to be stuck in the shoe. Resist the urge to use the lifting rig to "break" the mast free from the stuck base. It may take some precisely directed force to free a stuck mast base. Sometimes prying with a bar on the mast base may be enough or occasionally a judicious use of a mallet may cause the base let go.

Careful-If the lifting rig has been preloaded we risk the mast "jumping" when released.

As the mast rises it will clear the deck or mast base and it's time to pull the base toward one end of the boat and so mast can begin to be lowered and laid down.

You'll remember for a deck stepped mast we are controlling the lift from the winch at the base of the mast so you can just follow the mast base and be in control of the mast and the lowering at the same time. This saves a lot of time shouting commands.

Be prepared to remove delicate rig parts as they come into reach. Pay particular attention to the spreaders and radar.

Note-A keel stepped mast is more difficult as the rig must be lifted a couple meters to clear the deck. In this case we don't use the winch at the base of the mast but instead run our lifting line to the yachts largest winch. Maybe the windlass, or a large sheet winch. Keep in mind this will add weight to safety factor as the block tail is not lifting the mast, but instead it being fed to a winch.

To raise the mast simply just reverse the procedure.

To book a 2010 vacation contact Scott now.

|

This is a photo of a 40 ft mast being driven down the highway. This rig was built from scrap and made it all the way from San Francisco to Lap Paz Mexico. Another cruiser bought it, returned to Calif and brought his mast down. Don't know what happened to the rig after that.

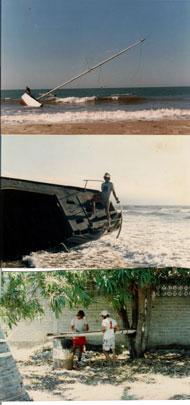

Here are some photos of the original mast when we salvaged it from a 1923 schooners in PV Mexico in 1987 or so. Notice in the middle photo above we went aloft to cut the stay connecting the two masts at the top. The halyards were already gone so this was a 65ft shimmy up a bare wood mast. It was great to be young.

Fifteen years later the mast seams began to fail in Costa Rica where the project below was completed.

Lowering the 600 KG mast and rig by using two sailboats at anchor.

This is how we moved the mast up and down the dock. These are our dingy landing wheels run through a piece of pipe to use as a mast mover. How about that old great bronze hardware. Once the mast was down we still had to use the mizzen to lift the base from the boat and set it on the dock. Our friends on Candlewin painting the bottom while we fixed our mast.

Here is how we built a trailer for a different mast

Working aloft takes planning and forethought.

Allison working out the lines

Articles originally published

in

Sailing forum links

|

|

||||

|

||||

| © Team Yachtwork 2009 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)